WATER,

SUNSHINE,

and

CARBON DIOXIDE

and create

WOOD

while generating

FRESH OXYGEN

for cleaner air.

Did you know?

In Washington, more than 12 million acres of forests are parks and other lands where trees cannot be harvested — an area larger than one million elementary schools?

A portion of the rest of Washington’s forestlands are “working forests.” These are the forests where we generate all of the wood that society needs for making a wide range of products that we cannot do without.

Working forests are carefully managed to be sure that we will always have healthy forests and wood for the future.

WHAT DO WE NEED WOOD FOR?

More than 5,000 products that we use every day and throughout the year are made using wood from trees. That’s right, and new uses for wood are being discovered every year.

Watch Kelly’s video below to learn more about many of the ways that wood is used.

Try these activities:

- How many items around can you identify that are made with wood?

- Make a list of wood products in your home.

- Write a story about wood.

- Research a wood item that comes from a tree.

- Do an art project with only tree products.

test your knowledge

What makes wood such a special and useful material?

Let’s learn more about what wood is made of.

WOOD = LIGNIN + CELLULOSE

Basically, the wood that we see when we look at something like a log is really the joining of two other substances called lignin and cellulose. While some products are made of wood in the form of lumber – such as for building houses or furniture – other products can only be made by separating the raw wood into these two other substances.

The bulk of a tree is made of tiny fibers of a substance called cellulose. Think of these cellulose fibers as being kind of like strings, but sturdy, and a substance that glues the fibers together and gives a tree its strength is called lignin.

When wood is cooked – heated, but not burned – lignin separates from the cellulose. The cellulose is then often used to make pulp for paper, but also in products like rayon fabric, toothpaste, or even football helmets. The lignin also has some pretty amazing uses. Compounds made with lignin are used in things ranging from cosmetics to medicine, and even to improve some foods.

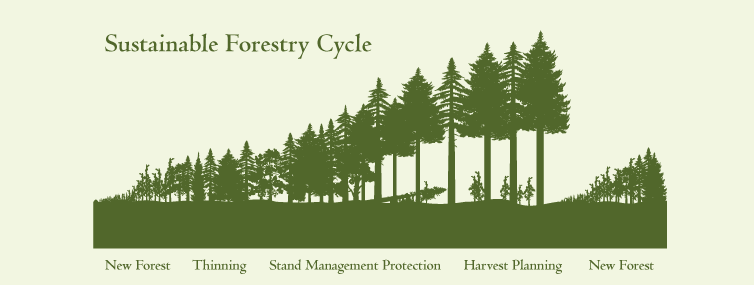

PLANT > GROW > HARVEST > RECYCLE & REPLANT

We'll start with some facts about harvesting.

The work of working forestry is a lot like farming, except that unlike a farmer who harvests and regrows a cornfield once every year, a single working forest will grow for 40, 50 or even 60 years or more before being harvested.

Prior to a harvest — a harvest is the part of the cycle when the trees are removed — careful plans are taken to protect fish and wildlife, water quality, and even archaeological or cultural sites on the land.

During the harvest, working foresters use what they have learned from science to care for the long-term health of their forests. For example, research found that birds and small animals will find good homes and thrive when we leave behind a number of trees, snags, and downed logs in harvested areas.

After the harvest, it's time to replant.

After trees are harvested, tree planters start the new forest growing again by replanting. Most of the trees that are planted get their start in a seedling nursery, where they are cared for up to 3 years before they are planted in the forest. On average, a tree planter can plant up to 1,500 seedlings in one day. More than 52 million trees are planted in Washington’s working forests each year.

The first tree farm — where replanting after a harvest was done — was established in Montesano, WA almost 80 years ago, in 1941.

Meanwhile, sawmills and factories get to work.

In the old days, the tools and machines that were available to cut whole logs into pieces of lumber that are useful for building and making many other wood products were much less sophisticated than now.

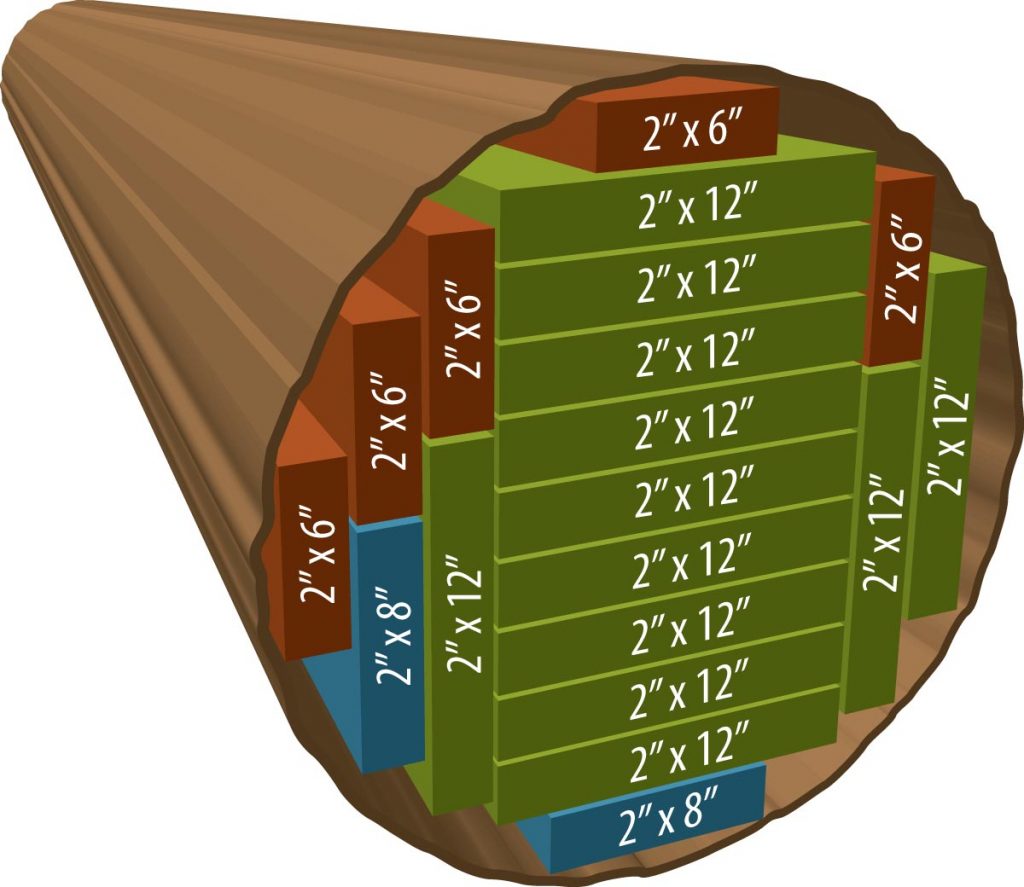

Today, lasers, computers, and precise cutting machines help to make sure every bit of each harvested tree is used and a goal of creating zero waste is more possible then ever before.

To the right is an illustration showing how a sawmill’s computers “see” every log and then create a plan to cut it into individual pieces, such as those used in building homes. And the areas that don’t have numbers on them aren’t wasted. That wood is saved — mostly as sawdust — when the log is sawmilled and is used in other important wood products.

from logs to lumber

Check out the video below. It was made by one of our Washington state companies. As you watch the path each log takes through a sawmill, pay attention to how in each step the machines are used to separate one component from the log. As you learned above, every one of these elements is needed in the manufacturing of a wood product

Most people now agree that climate change is something we need to address.

LET’S LEARN HOW NATURE AND SCIENCE WORK TOGETHER IN OUR FOREST SECTOR ON CARBON AND CLIMATE CHANGE.

Because of science that we've had for a very long time, we know that wood products store carbon. But there's more.

Trees in healthy forests absorb carbon and give off oxygen. You might have already learned from a teacher in school about photosynthesis — the process by which trees use sunlight to take carbon from the atmosphere and then release oxygen back into the air. In this process, the carbon is stored in the wood of the tree — as it continues to grow. That carbon stays there until the wood decays or is burned.

What we didn’t know until recently was how much using more wood in society can help reduce the amount of carbon our state emits.

New science from the University of Washington found that when private working forests are harvested and replanted, and wood is used for building, the result is that we reduce Washington’s overall carbon emissions by 12% on average every year.

What we now know is that growing forests pull carbon from the atmosphere, the harvested wood stores carbon in the products that we buy. Then we replant the forest so that new trees pull more carbon, and the cycle starts over again.